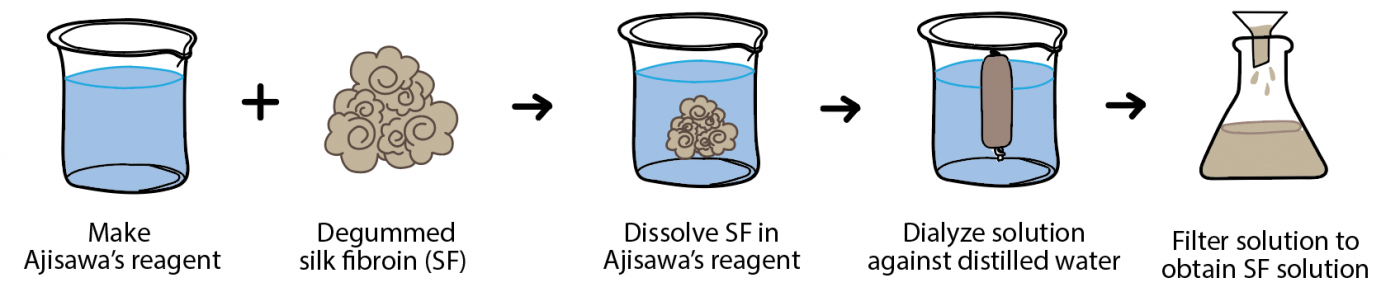

Prepare Silk Fibroin

Background

Silk fibroin is a protein secreted by silkworms and can be collected from cocoons. Known for its biocompatibility and durable mechanical properties, silk fibroin has been attracting attention from a variety of industries, from textile to medical engineering. How, then, is it prepared for industrial use after getting extracted from a cocoon? Read below to follow the steps of preparing silk fibroin for use!

Materials

Ingredients

- Degummed silk fibroin

- Distilled water

- 23 g of calcium chloride

- 30 mL of ethanol

Equipment

- Oven

- Two dialysis clamps

- Dialyses tubing

- Balance

- 50 mL beakers

- Centrifuge

Protocol

- Combine distilled water, calcium chloride, and ethanol together. The resulting solution is called an Ajisawa’s reagent.

- Pack 5 g of degummed silk fibroin tightly into a 50 mL beaker.

- Pour 20 mL of the Ajisawa’s reagent into the beaker, making sure the silk fibroin is completely submerged.

- Place the beaker in the oven at 60°C for 4 hours or until all the fibroin has dissolved.

- Cut the dialysis tubing so that it fits into the beaker, and then hydrate it in the beaker containing the silk fibroin. Clamp one end tightly with a dialysis clamp.

- Let the solution cool, then carefully pour the solution into the dialysis tubing and clamp the other end.

- Dialyze against 1 L of distilled water. Change the water after 1 hour, 4 hours, that evening, the next morning and night, as well as in the morning on the following day (six changes total within 48 hrs).

- Place silk in a 50 ml conical tube. You may need to split it between two tubes if it is more than 40 ml, alternatively you can fill one tube and use a counterbalance of water.

- Centrifuge to remove impurities. Place in a centrifuge and spin at 9,000 r.p.m. (~12,700g) at 4 °C for 20 min.

The final product is a purified silk fibroin solution that is ready for industrial use!